Calibrate Servo

Fine-tune servo positions and limits

Calibrate Servo

Fine-tune servo motor positions, limits, and mechanical center points.

Pro Tip

Always leave a 5-10° safety margin from mechanical limits. Servos that hit hard stops generate high current draw and can damage the motor, gears, or connected structure.

Why calibrate?

Servos need calibration because:

- Mechanical tolerances - Each servo is slightly different

- Mounting offsets - Physical installation affects center point

- Safety limits - Prevent damage from over-rotation

- Accurate control - Ensure 90° actually means 90°

Prerequisites

- Servo added to Agent (see Add Actuator)

- Agent running with controller connected

- Physical access to the robot

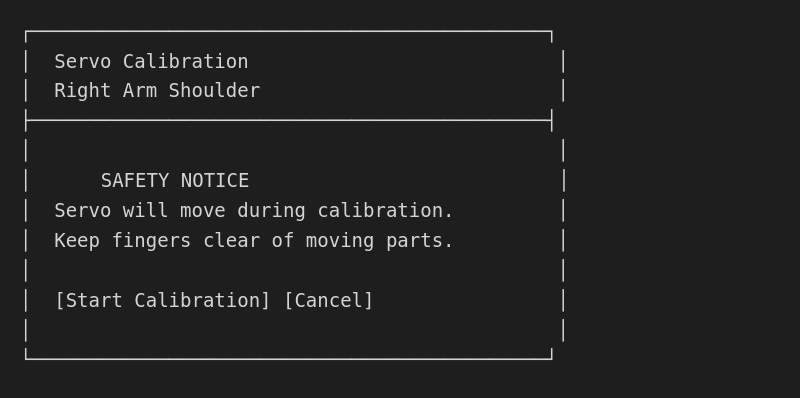

Step 1: Enter calibration mode

On the Agent:

- Open ☰ Menu → Settings

- Go to Hardware → Actuators

- Select the servo to calibrate

- Tap [Calibrate]

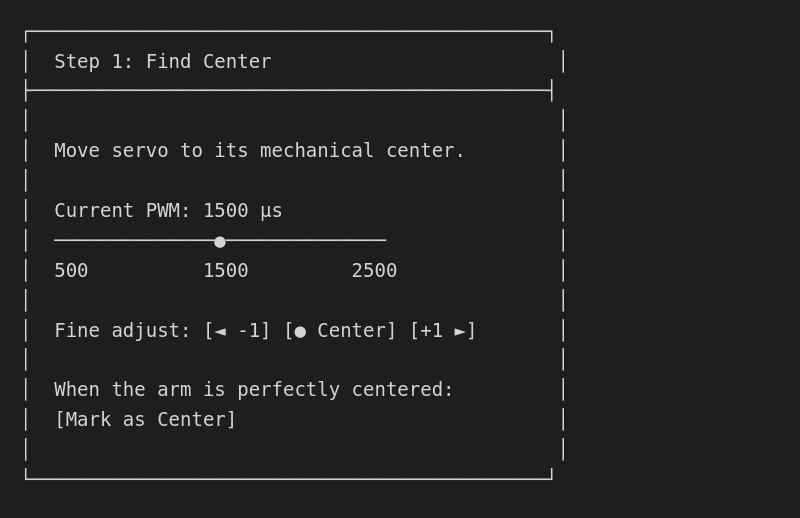

Step 2: Find mechanical center

First, establish the true center position:

Finding true center

- Move slider until the physical arm is at its center position

- For robot arms: usually perpendicular to body

- For pan/tilt: usually straight ahead

- For continuous rotation servos: where motor stops

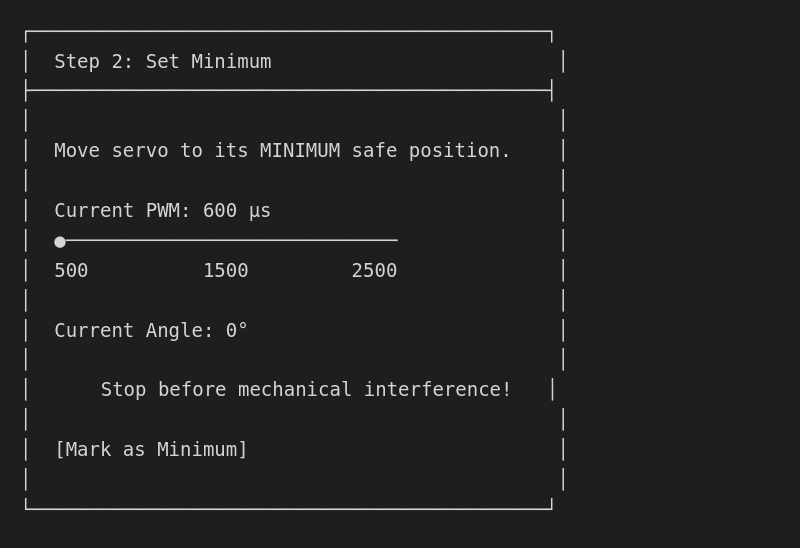

Step 3: Set minimum limit

Find the safe minimum position:

Setting safe minimum

- Slowly decrease PWM value

- Watch for mechanical limits (collision, strain)

- Stop before hitting hard limits

- Leave ~5° margin for safety

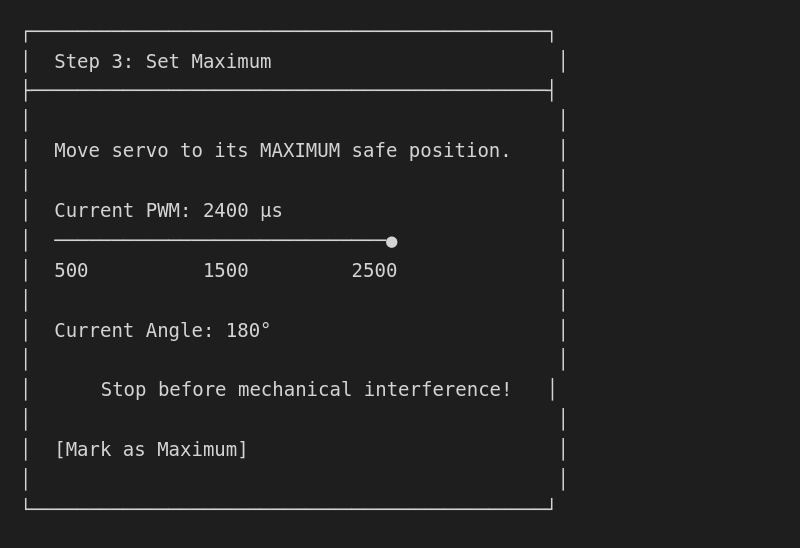

Step 4: Set maximum limit

Find the safe maximum position:

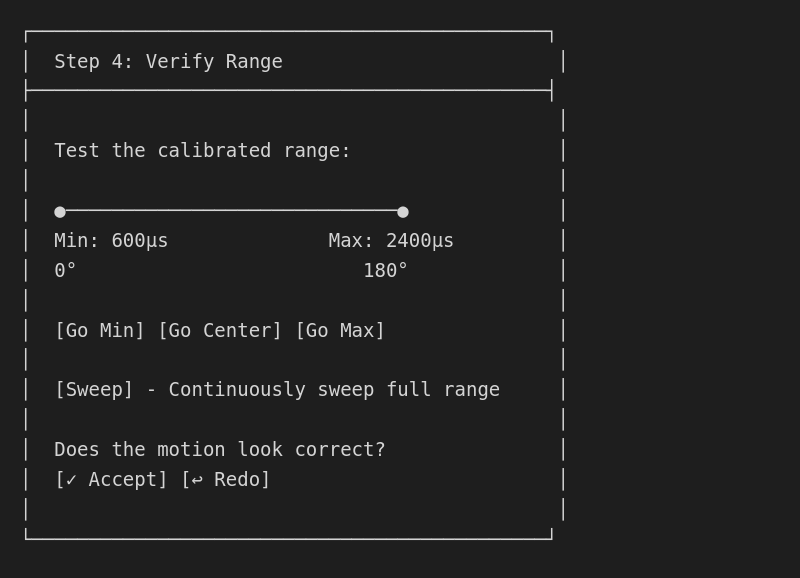

Step 5: Verify range

Test the full range of motion:

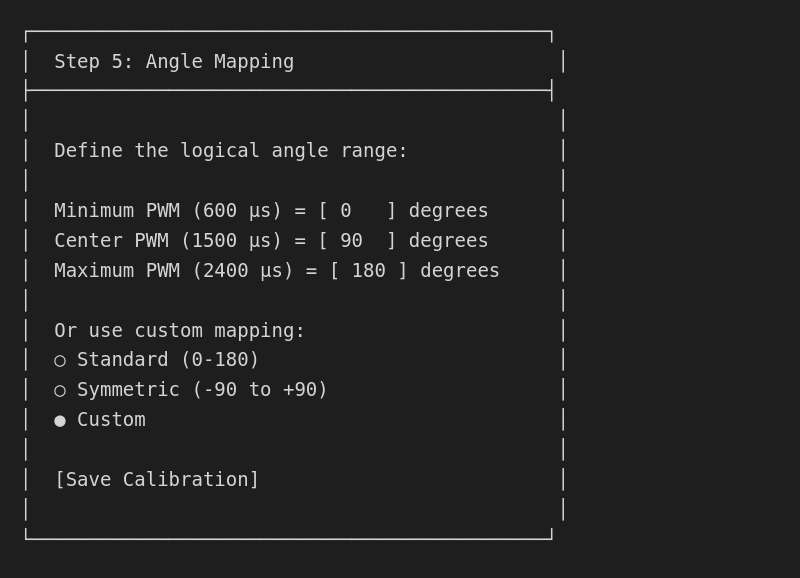

Step 6: Set angle mapping

Map PWM values to logical angles:

Common angle mappings

| Use Case | Min | Center | Max |

|---|---|---|---|

| Standard servo | 0° | 90° | 180° |

| Symmetric pan | -90° | 0° | +90° |

| Limited tilt | -45° | 0° | +45° |

| Gripper | 0° (closed) | - | 60° (open) |

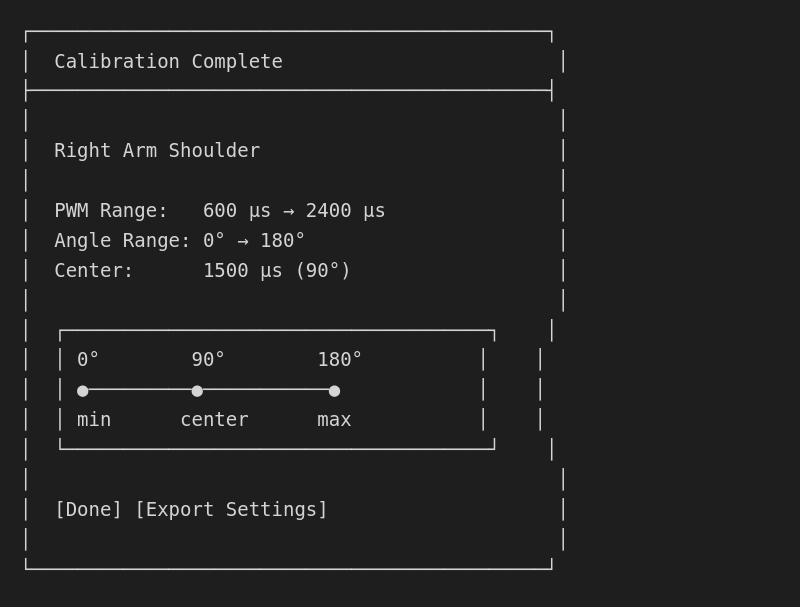

Calibration summary

After calibration:

Calibrating multiple servos

Sequential calibration

Calibrate each servo individually for precision:

- Start with base/root joints

- Move outward to end effectors

- Lock calibrated joints during later calibration

Calibration order for robot arm

| Order | Joint | Notes |

|---|---|---|

| 1 | Base Rotation | Mount arm vertical for this |

| 2 | Shoulder | Rest arm on support |

| 3 | Elbow | Shoulder at 90° |

| 4 | Wrist | Arm extended |

| 5 | Gripper | Last, least critical |

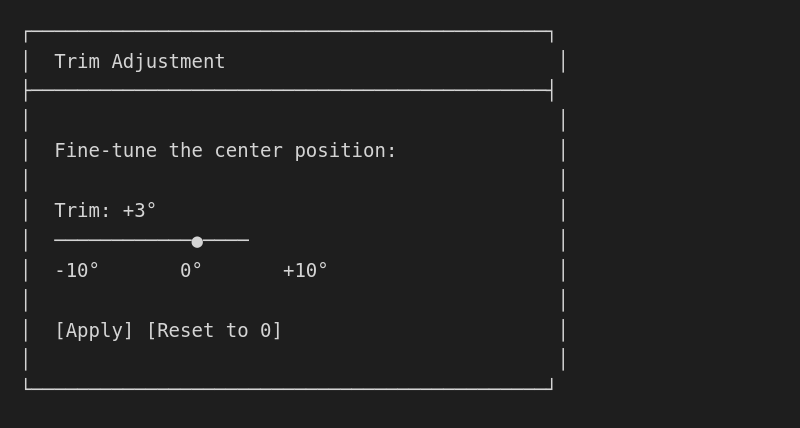

Trim adjustment

For minor adjustments after initial calibration:

- Open actuator settings

- Tap [Trim]

- Adjust the center offset

Troubleshooting calibration

Servo won't move during calibration

- Power issue - Check power supply

- Connection - Verify controller connection

- Pin conflict - Check no other software uses the pin

Servo moves erratically

- Power supply - Use dedicated servo power

- Ground loop - Common ground between controller and servo power

- PWM frequency - Standard servos need 50Hz

Center doesn't match physical center

- Servo horn offset - Remove and reattach horn at center

- Gear slippage - Check for worn splines

- Use trim - For minor misalignment

Range seems limited

- PWM limits - Some servos need 400-2600µs

- Mechanical binding - Check for obstructions

- Servo specification - Some servos are <180°

Calibration data storage

Calibration is saved in:

~/.local/share/OctoMY™/OctoMY Agent/<personality>/hardware.json

Example calibration data:

{

"actuators": [

{

"name": "Right Arm Shoulder",

"type": "servo",

"pin": 3,

"calibration": {

"minPwm": 600,

"maxPwm": 2400,

"centerPwm": 1500,

"minAngle": 0,

"maxAngle": 180,

"trim": 3,

"inverted": false

}

}

]

}

Backup and restore

Export calibration

# Copy calibration to backup

cp ~/.local/share/OctoMY™/OctoMY\ Agent/MyRobot/hardware.json \

~/octomy-calibration-backup.json

Restore calibration

# Restore from backup

cp ~/octomy-calibration-backup.json \

~/.local/share/OctoMY™/OctoMY\ Agent/MyRobot/hardware.json

Transfer to another robot

Same model robots can share calibration:

# On source robot

scp hardware.json user@target:~/

# On target robot

cp ~/hardware.json ~/.local/share/OctoMY™/OctoMY\ Agent/NewRobot/